Testing

We put the 8100 through our usual series of tests, dealing with acrylic and metals and even used a reinforced cutting disc to see how it fared with a small amount of steel. If the neighbours have been complaining about the noise your corded Dremel makes, then the 8100 is likely to give you a get of of jail free card - it's a lot quieter than any other rotary tool we've used, even at 30,000 rpm.The lack of torque was immediately noticeable compared to the Dremel 3000 we had to hand, but was more of a matter of getting used to it rather than it being a complete disadvantage. It was certainly less scary to use, but if you're man enough to handle a corded tool, then you'll certainly be able to eat into tougher materials much more rapidly. Plastics were no trouble at all, with the 8100 coping with a long section of acrylic just as well as the corded Dremel 3000.

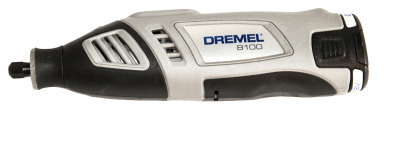

Click to enlarge

Sheet aluminium was also no problem although the corded 3000 was noticeably more capable here, with the additional torque allowing us to complete the task of cutting a few inches of 3mm sheet in much less time. The sanding and grinding attachments are probably the 8100's natural environment as they don't need a lot of power to work well. It was certainly a pleasant change not to have a cable to deal with.

Turning our attention to steel, however, was a different story. We were initially surprised that it managed to chomp its way through 1mm steel quite readily, however after about 30 seconds the 8100 became exceedingly hot then stopped working. Powering it off then on again seemed to fix things but it would do this after a few seconds dealing with the steel so it's clear there's a temperature cut-off preventing damage to the motor and bearings.

Click to enlarge

The Detail Grip attachment worked well though and the 8100's low weight was a real asset in dealing with finer cutting and sanding. We can report that it works fine with other attachments such as the Flexible Shaft too. The battery lasted a good 40 minutes before it began to give out - a reasonable amount of time that should allow you to complete most simple tasks, especially in softer materials.

Click to enlarge

Conclusion

We were pleasantly surprised by the Dremel 8100 in that it was actually able to cope with some fairly tough materials and lasted a fair amount of time on it's 7.2V battery. However, we found its limits pretty quickly - it's simply not designed to deal with sheet metal, and it actually powered off when we tried our hand at some fairly thin steel, although this appeared to be more of an issue with it overheating than the motor not being powerful enough.

For a light use rotary tool, the 8100 is still pretty flexible. The fact you can just power it on and go with no worry about whether the cable will reach is obviously very appealing, especially for odd jobs that don't take hours or need oodles of power. Sanding and cutting wood or plastic should see well over half an hour or more of solid use. That said, unless you're hell-bent on going cordless, the Dremel 3000 is a better tool in nearly every way and costs less too.

-

Features24 / 30

-

Design33 / 40

-

Value23 / 30

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.